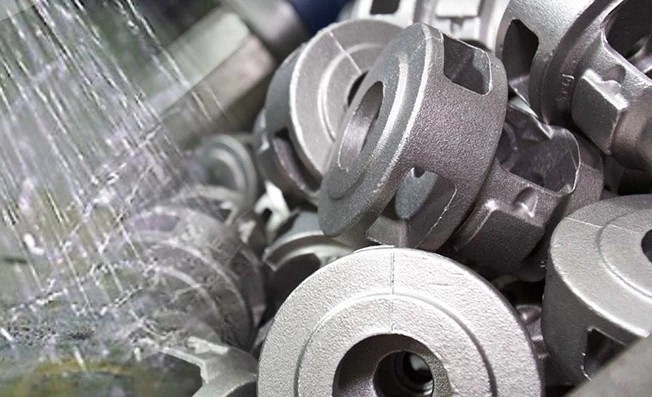

Shot Peening, Stress Relieving of Connecting Rod

1)What is shot peening?

The terms ‘Shot Peening’ and ‘Shot Blasting ’ are easily conflated due to with similar names and styles of operation. So What are the differences between them and why shot peening, is a helper for high quality connecting rods? This passage reveals for you.

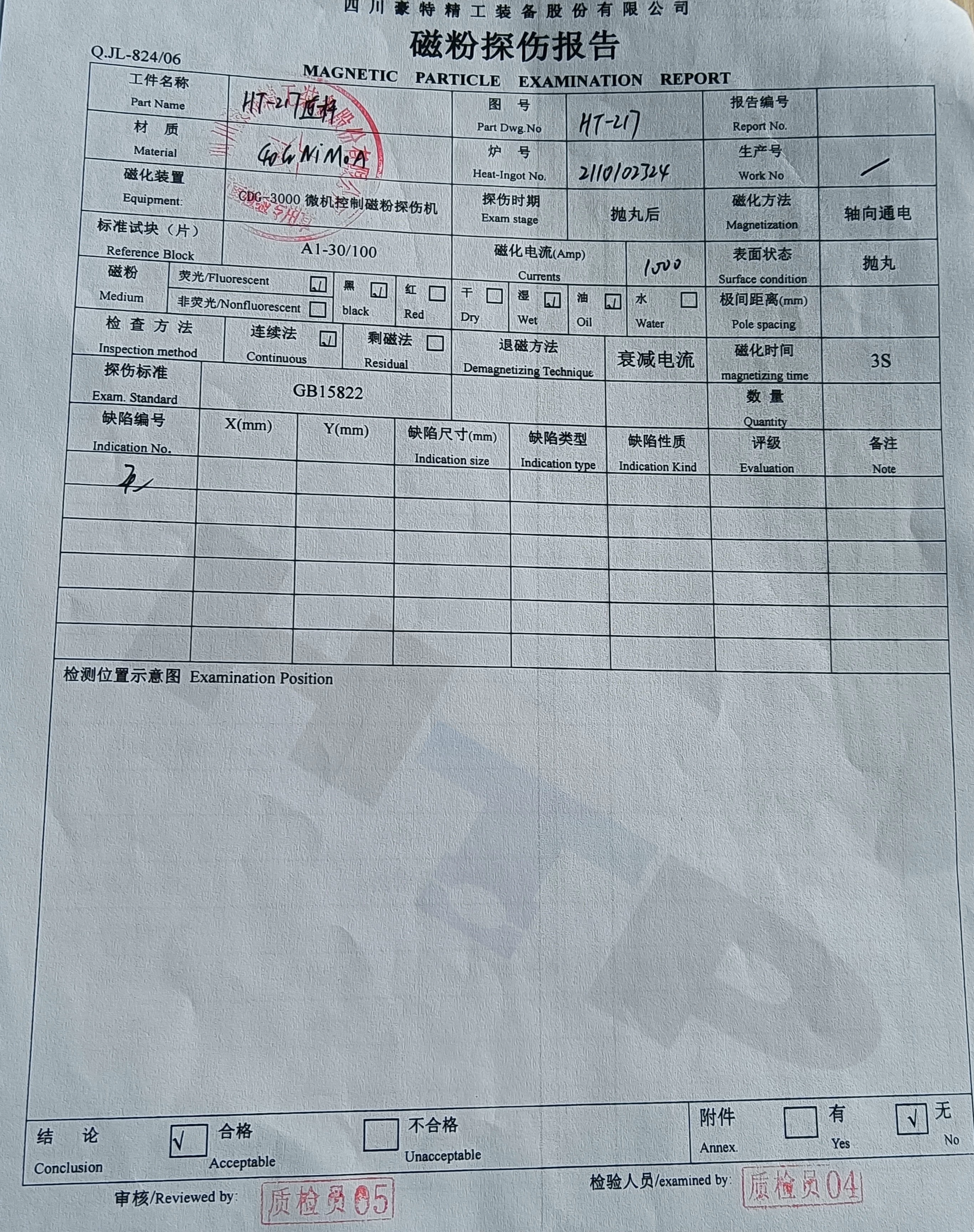

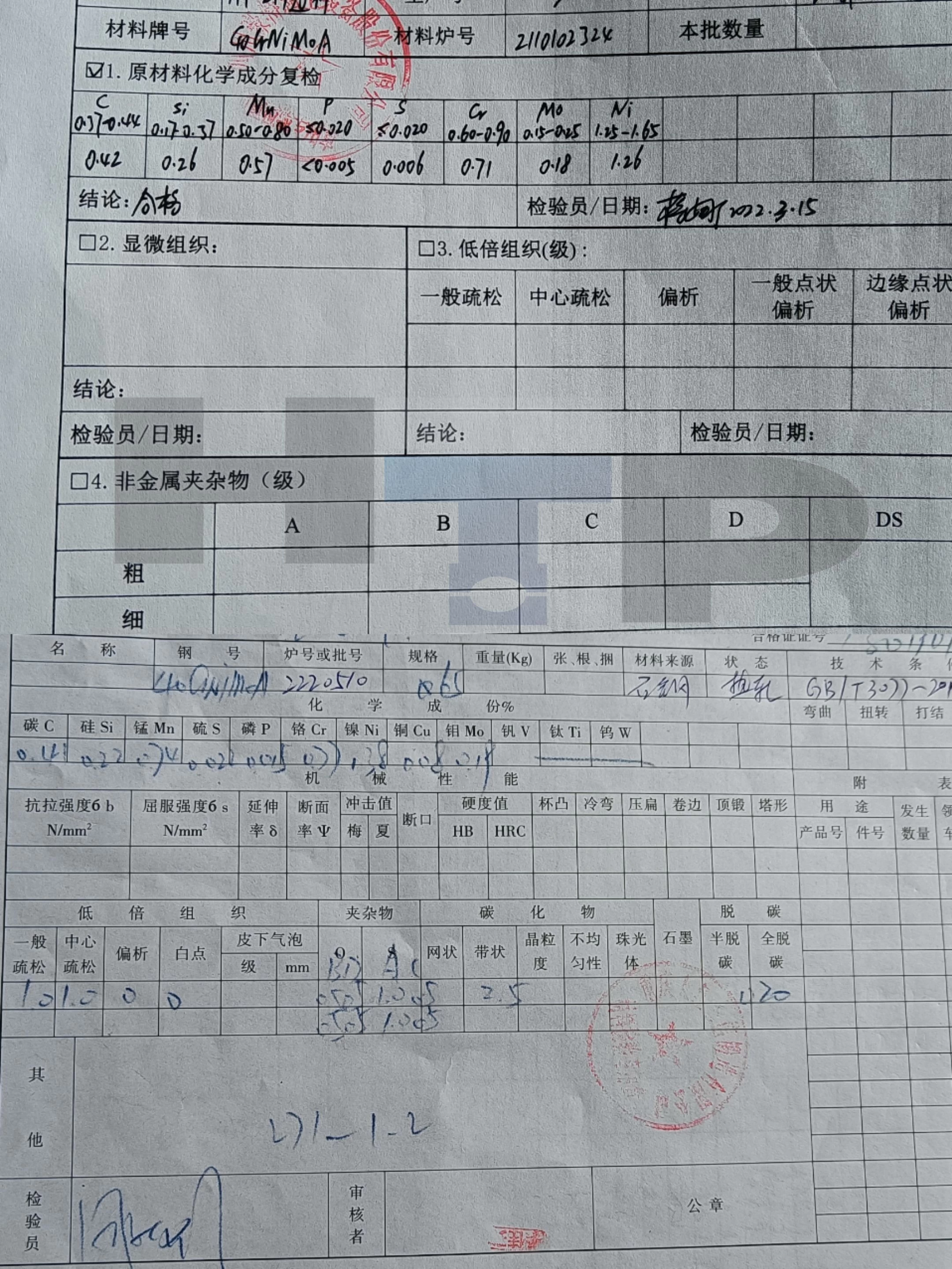

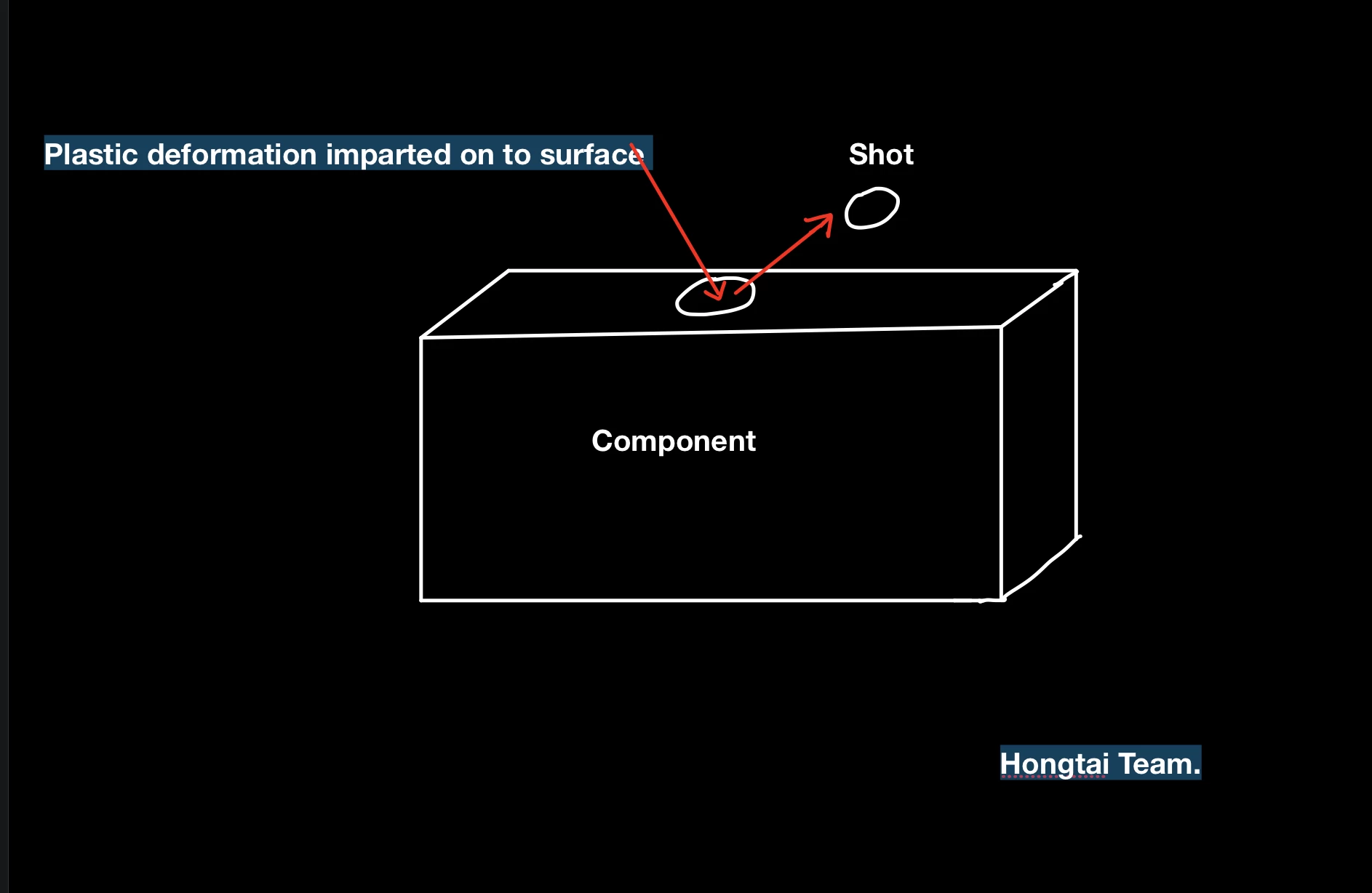

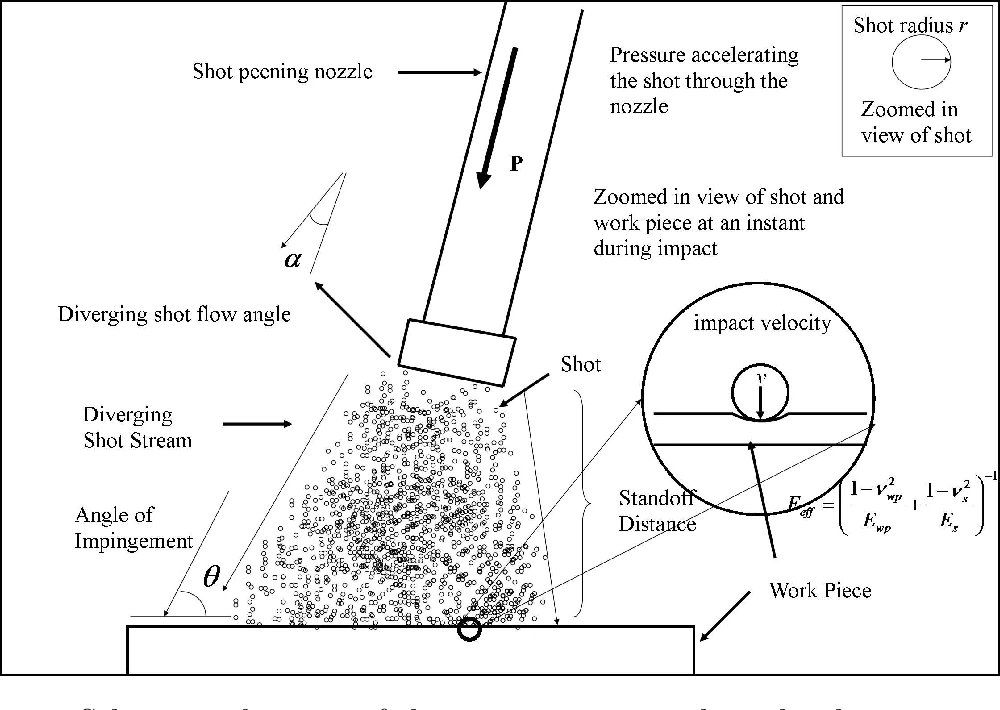

Shot Blasting: It works on the principle of abrasion. A stream of abrasive particles are propelled under high pressure on to the surface of a component to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants. Shot Peening: Shot peening used to produce a compressed layer and change properties of a metal. It is a process that is precisely controlled by a careful selection of media, along with controlled intensity. It is a cold process stress on the surface of metals. Shot peening uses steel ‘shots’ that are accelerated to the surface, this means that no dust is created and causes less pollution compared to sandblasting.

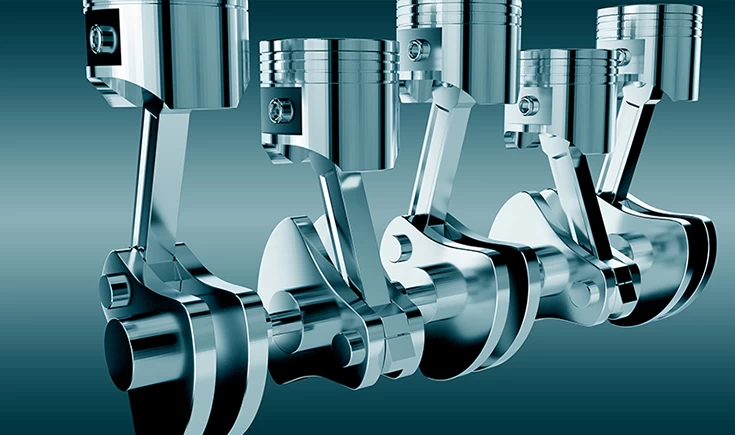

2)Why shot penning is good for connecting rod?

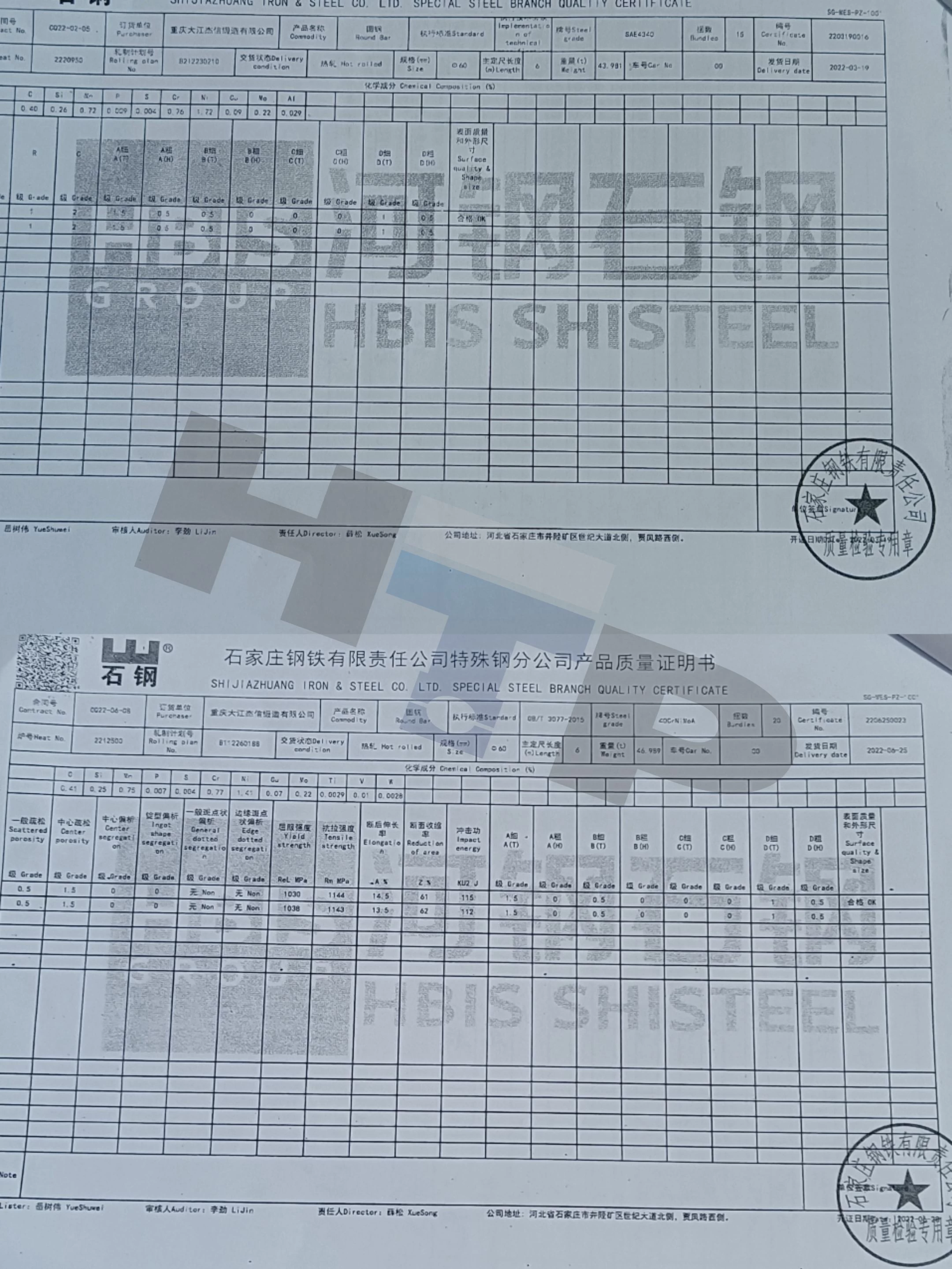

Connecting rod as a key part to connect the crankshaft and piston, more extreme engine loads to be taken on, which requires high performance rods must be precisely finished to ensure a tight fight and to withstand any stress placed on the part while in use. Shot peening for rod, its effectiveness lies into improve fatigue life; prevent cracking due to wear and tear, and also inhibit hydrogen embrittlement, fretting, and galling for rod.

3)How shot penning works?

Quality is the Soul of an Enterprise. The pursuit of high quality is a mission of Hongtai Performance. Under the mission, the connecting rods of Hongtai Performace are shot peened fully with steel balls during the production to improve fatigue life to enhance strength , and also make the rods more beautiful and smooth. Here is a video to show how shot penning works in Hongtai Performace Factory.